By: Christina Olivarria

The term value engineering is often used by project teams to describe a method of effectively cutting project costs. Value engineering is defined as a systematic approach to eliminating unnecessary costs and poor performing components. When approaching new healthcare facility construction projects, multidisciplinary teams can utilize value engineering both to reduce overall project costs and design a space that is valuable both to the patients and staff who bring these spaces to life.

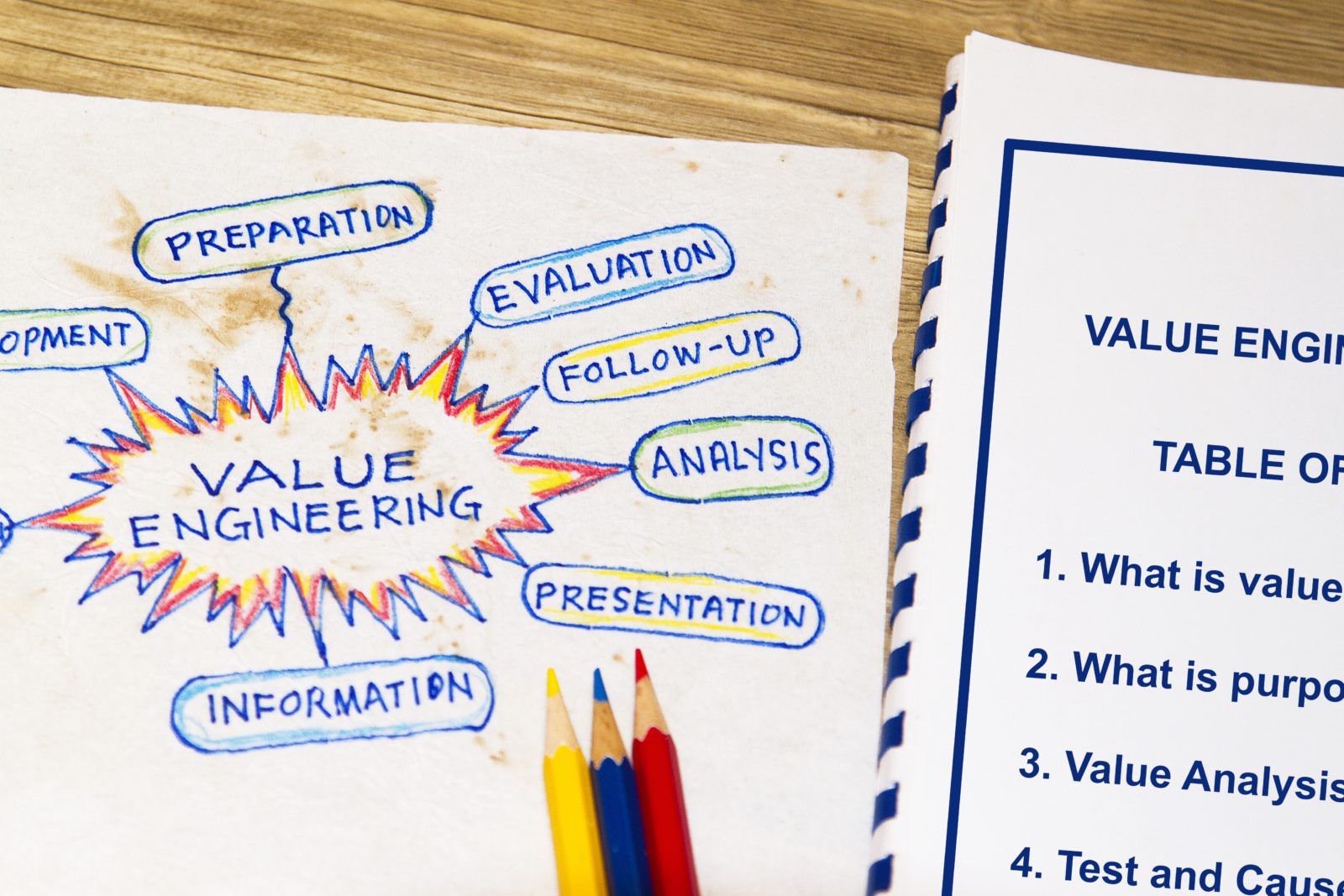

For this blog post, value engineering’s benefits will be demonstrated using the example of a new hospital being designed. Following the value engineering process of information gathering, functional analysis, brainstorming, analysis, and recommendations, project design teams can identify areas of opportunity and then create a project plan that fulfills the healthcare organization’s requirements and maximizes value for the organization.

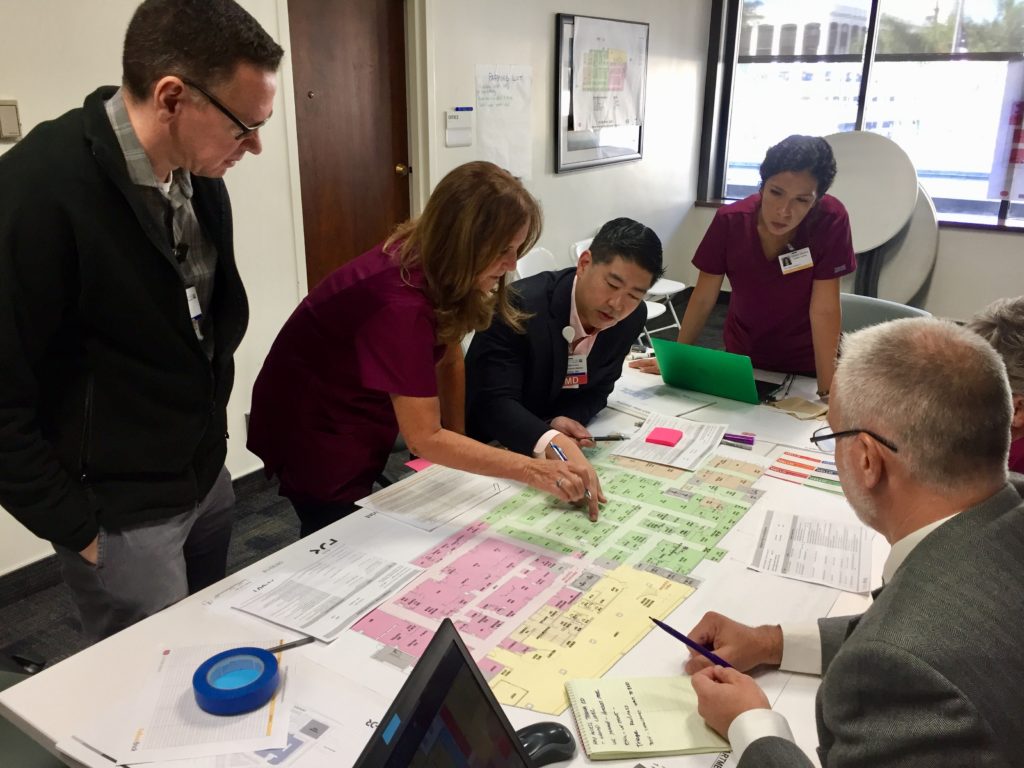

A key first step before beginning the value engineering process is identifying the key players that need to partake in the design project. For the project being discussed, stakeholders from the architecture firm, general contracting company, owner’s representation firm, hospital administration, and clinical and regulatory teams should all be represented when conducting a value engineering workshop. In addition, the organization may choose to engage a business relationship manager to assist in identifying opportunities to create business value.

Once the stakeholders have been identified, the value engineering team will identify and define the project, it’s components and the functions. This phase will also explore the project’s budget and schedule and will identify any constraints. Having a multidisciplinary team to assist with this process ensures that the project considers various perspectives, and in the case of the project example, identifies end-user needs as well as regulatory compliance requirements.

The second phase of the value engineering process is functional analysis. A component’s function is defined as the use of a part of a product and the esteem value that it provides. The value engineering team(s) review the requirements identified in the information-gathering phase and their intended function. There are three types of functions:

- basic function

- required secondary function

- secondary functions

A key question the team asks themselves during this phase is whether a function can be removed without impacting the project? A tool that the value engineering team can use during this phase is the FAST (Function Analysis System Technique) diagram. This flowchart-style tool is used to help value engineering teams distinguish the functions that are required, versus the functions that are wanted.

After the functions have all been identified, the value engineering teams can then brainstorm and create solutions that identify opportunities for value engineering. In the example of the hospital construction project, the project team can review the requested IT components, and based on the required and desired functions, the team may choose alternate models that are comparable in function but cost less. Some questions that teams may use to guide this process include:

- What is it?

- What does it cost?

- What does it do (i.e., why is it required)?

- What is it worth?

- What else would do the job?

The analysis phase of value engineering takes the creative ideas and concepts discussed during the brainstorming phase and analyzes them further to create meaningful and impactful solutions. In healthcare design, a method used during this phase is called Tabletop exercises. Using scripted scenarios, value engineering teams validate their ideas by incorporating clinical end-users in the process. Gaps in functionality are identified, as well as opportunities to increase patient value by reducing process steps or adjusting department adjacencies. It is imperative that the business relationship manager participates in these sessions to ensure that the solutions discussed align with the organization’s overall business strategy and definitions of value.

The final phase of value engineering is the presentation and implementation of the value engineering plan. The plan should address the questions of how the proposed alternatives address requirements. Factors such as quality, durability, maintainability, and reliability should be addressed in the plan as well as cost estimates. Once approved, the business relationship manager can then oversee that the action plan is put into place by a project team, and report back regularly to organizational leadership about the effectiveness of the plan.

By utilizing value engineering during design, healthcare project teams can reduce both the unnecessary costs of projects caused by a poor understanding of user requirements and also increase the sense of teamwork and comradery on a project team. Engaging a team of interdisciplinary stakeholders in the design process and facilitating an open dialogue about the users’ needs and wants for the components that make up the project will reduce the number of user change requests once the project has been built and will increase stakeholder buy-in.

References:

Sievert, R. W. (1991). A review of value engineering as an effective system for planning building projects. Project Management Journal, 22(1), 31–38.

Sanam Ziyaeidustan, Abbas Mahmoudabadi. Application of Value Engineering to Improve Discharging Procedure in Healthcare Centers (Case Study: Amini Hospital, Langroud, Iran). International Journal of Engineering Management. Vol. 1, No. 1, 2017, pp. 1-10. doi: 10.11648/j.ijem.20170101.11

Luoma, H. (2005). The good and the bad of value engineering. Retrieved from Healthcare Design: https://www.healthcaredesignmagazine.com/architecture/good-and-bad-value-engineering/